Product Description

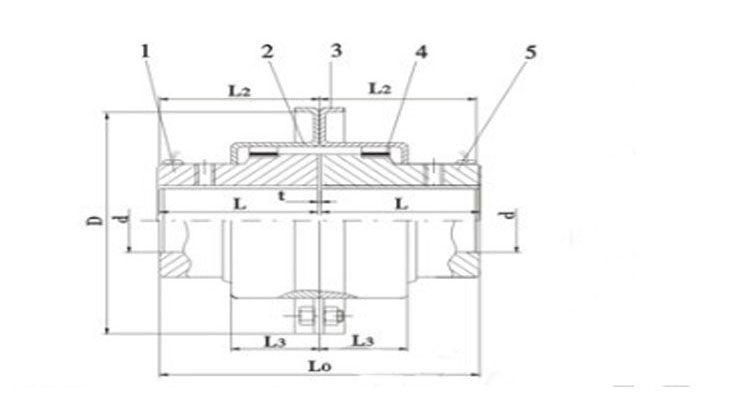

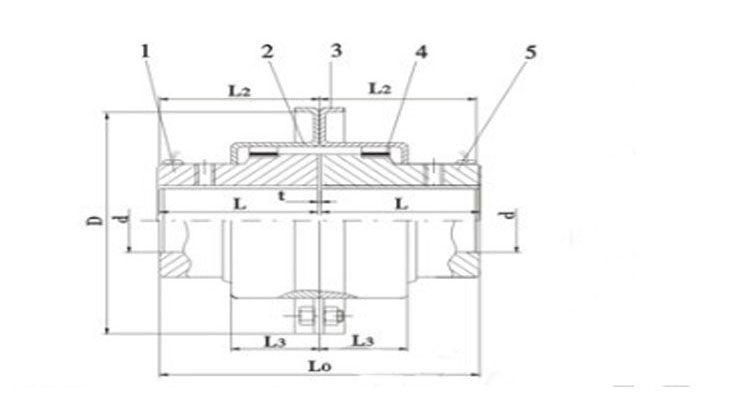

The JSB Snake Spring Grid Coupling is called "JB/T coupling".

Unlike JS serpentine couplings, it is installed in horizontal

direction and JSB type snake spring couplings are installed

vertically.

The JSB Snake Spring Grid Coupling is suitable for working

conditions such as temperature, humidity, water, steam, dust, sand,

oil, acid, alkali, corrosive medium, brine, radiation and so on.

For the working quality of high temperature, low temperature, oil,

acid and alkali medium, it is not suitable for flexible coupling

with general rubber as elastic element material. Flexible metal

flexible coupling, such as diaphragm coupling and snake spring

coupling, should be selected.

JSB Snake Spring Grid Coupling is mainly applied to the crusher,

the crank reciprocating motion, speed reducer, metallurgy, mining,

crane and other equipment, the drive shaft connecting two coaxial,

high power, with a certain offset and compensate the relative

damping and buffering performance, the working temperature is -30

DEG ~+150 DEG, nominal torque transmission 45~800000N.m.

|

| Size | Torque Tn KN.m | Speed (n) r/min | Bore d | Length L | Total lenght L0 | L2 | L3 | D | t | Weight kg | Oil injection kg | Allowable displacement |

| Radial y | Axial x | Angular a |

| JSB1 | 0.045 | 6000 | 18-28 | 47 | 97 | 48 | 24 | 112 | 3 | 2 | 0.027 | 0.15 | ±0.3 | 0.076 |

| JSB2 | 0.14 | 6000 | 22-35 | 47 | 97 | 48 | 25 | 122 | 3 | 2.6 | 0.048 | 0.15 | ±0.3 | 0.076 |

| JSB3 | 0.224 | 6000 | 25-42 | 50 | 103 | 51 | 26 | 130 | 3 | 3.4 | 0.054 | 0.15 | ±0.3 | 0.076 |

| JSB4 | 0.4 | 6000 | 32-50 | 60 | 123 | 61 | 31 | 149 | 3 | 5.5 | 0.068 | 0.2 | ±0.3 | 0.1 |

| JSB5 | 0.63 | 6000 | 40-56 | 63 | 129 | 64 | 32 | 163 | 3 | 7.3 | 0.086 | 0.2 | ±0.3 | 0.127 |

| JSB6 | 0.9 | 5500 | 48-65 | 76 | 155 | 67 | 34 | 174 | 3 | 10 | 0.113 | 0.2 | ±0.3 | 0.127 |

| JSB7 | 1.8 | 4750 | 55-80 | 89 | 181 | 89 | 44 | 200 | 3 | 18 | 0.172 | 0.2 | ±0.3 | 0.15 |

| JSB8 | 3.15 | 4000 | 65-95 | 98 | 199 | 96 | 47 | 233 | 3 | 26 | 0.254 | 0.2 | ±0.3 | 0.18 |

| JSB9 | 5.6 | 3250 | 75-110 | 120 | 245 | 121 | 60 | 268 | 6 | 42 | 0.427 | 0.25 | ±0.5 | 0.2 |

| JSB10 | 8 | 3000 | 80-120 | 127 | 259 | 124 | 63 | 287 | 6 | 55 | 0.508 | 0.25 | ±0.5 | 0.23 |

| JSB11 | 12.5 | 2700 | 90-140 | 149 | 304 | 143 | 74 | 320 | 6 | 82 | 0.735 | 0.28 | ±0.5 | 0.25 |

| JSB12 | 18 | 2400 | 110-170 | 162 | 330 | 146 | 75 | 379 | 6 | 123 | 0.908 | 0.28 | ±0.5 | 0.3 |

| JSB13 | 25 | 2200 | 120-200 | 184 | 374 | 156 | 78 | 411 | 6 | 180 | 1.135 | 0.28 | ±0.5 | 0.33 |

| JSB14 | 35.5 | 2000 | 140-200 | 183 | 372 | 204 | 107 | 476 | 6 | 230 | 1.952 | 0.3 | ±0.5 | 0.4 |

| JSB15 | 50 | 1750 | 160-240 | 216 | 438 | 216 | 115 | 533 | 6 | 322 | 2.815 | 0.3 | ±0.5 | 0.45 |

| JSB16 | 63 | 1600 | 180-260 | 216 | 438 | 226 | 120 | 584 | 6 | 449 | 3.496 | 0.3 | ±0.5 | 0.5 |

About Us

More application scenarios, please contact us